Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

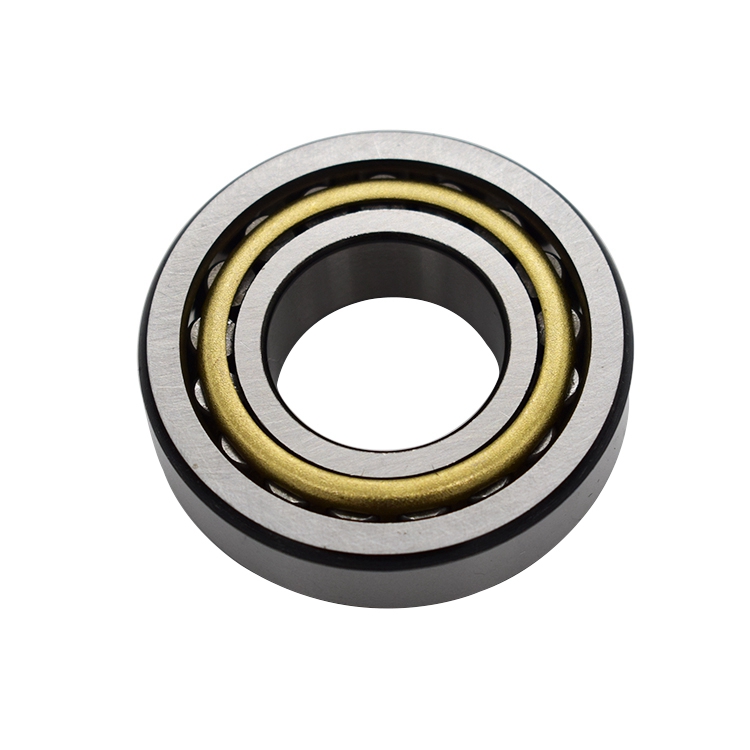

First, the installation environment of the bearing: the installation of the bearing must be carried out under dry and clean environmental conditions. Before installation, carefully check the processing quality of the mating surface of the shaft and the housing, the end face of the shoulder, the groove and the connection surface. All mating connection surfaces must be carefully cleaned and deburred, and the unprocessed surface of the casting must be cleaned of molding sand.

When installing the bearing, it is necessary to apply equal pressure on the circumference of the end face of the ferrule to press the ferrule in. Do not directly hit the end face of the bearing with a hammer head or other tools to avoid damage to the bearing. In the case of small interference, the sleeve can be used to press the end face of the bearing ring at room temperature, and the sleeve can be tapped with a hammer head to press the ring evenly through the sleeve. If it is installed in large quantities, a hydraulic press can be used. When pressing in, it should be ensured that the end face of the outer ring and the shoulder end face of the shell, and the end face of the inner ring and the shoulder end face of the shaft are pressed tightly, and no gap is allowed.

The clearance should be adjusted at the end of single row tapered roller bearing installation. The clearance value should be determined specifically according to different operating conditions and the size of the interference fit.

September 06, 2022

August 18, 2022

이 업체에게 이메일로 보내기

September 06, 2022

August 18, 2022

November 07, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.